Power Steering Pump Tester PT 51

{Copyright (C) 2007 Avanquest Software, Inc. All Rights Reserved}

GEI Systems, Inc

To test hydraulic power steering pumps the following major components have been used:

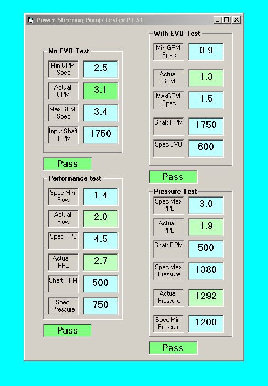

Max. Flow Test. With no load applied to the output port during this test, the computer controls RPM level at the electrical DC drive and measures the amount of flow through the unit as well as the amount of torque required to turn the pump. That indicates the quality of the assembled unit.

High pressure Test. During this test the computer sets a desired RPM and shuts off the output port of the pump and monitors the pressure level at the output port to test the internal relief valve built in the pump.

Performance Test. During this test the computer controls both parameters: RPM of the pump shaft and output pressure at the output port. For every pair of command parameters the computer stores the output parameters: flow level through the pump and torque required by the motor to run at the preset RPM to create performance curves of the unit.

As an option, the pressure pulse level PPL sensor for a hydraulic noise measurement can be installed.

Some of the latest model pumps have a built in EVO valve which allows ECU to modify certain pump design characteristics during the steering process. For those cases GEI offers an optional control channel to verify the pump's performance at different settings of this valve.

- DC motor as a source of RPM to simulate the engine drive;

- Flow control valve to create a desired load on the pump;

- Instrumentation: pressure sensors, flow meters, torque sensor, etc.

Max. Flow Test. With no load applied to the output port during this test, the computer controls RPM level at the electrical DC drive and measures the amount of flow through the unit as well as the amount of torque required to turn the pump. That indicates the quality of the assembled unit.

High pressure Test. During this test the computer sets a desired RPM and shuts off the output port of the pump and monitors the pressure level at the output port to test the internal relief valve built in the pump.

Performance Test. During this test the computer controls both parameters: RPM of the pump shaft and output pressure at the output port. For every pair of command parameters the computer stores the output parameters: flow level through the pump and torque required by the motor to run at the preset RPM to create performance curves of the unit.

As an option, the pressure pulse level PPL sensor for a hydraulic noise measurement can be installed.

Some of the latest model pumps have a built in EVO valve which allows ECU to modify certain pump design characteristics during the steering process. For those cases GEI offers an optional control channel to verify the pump's performance at different settings of this valve.

Phone:(612) 922-7816

Fax: (612) 920-7955

E-mail: info@geisystem.com

Fax: (612) 920-7955

E-mail: info@geisystem.com